Understanding Propane Tank Filling: Safety And Best Practices

Propane remains a dependable fuel source for homes, businesses, and farms. From heating to powering appliances, it plays a large role in daily life. Yet, safety must always guide the process of filling a propane tank.

Careful handling reduces risks and promotes efficiency, while mistakes can create hazards. Knowing proper techniques protects both people and property. Studying best practices makes small details easier to manage, leading to a safer experience.

This guide explores filling procedures, storage practices, and long-term safety habits.

Why Safe Propane Handling Matters

Propane is highly flammable and stored under pressure. Even a minor leak can spread quickly, and an uncontrolled release of gas increases the chance of fire or explosion. Safe filling practices lower these risks by keeping tanks in good condition and preventing overfills.

Another reason lies in propane’s widespread use. Many homes in Pennsylvania and Maryland depend on it for heating, water systems, and cooking. Businesses rely on propane for forklifts, generators, and seasonal equipment. Farms use it for grain drying and building heat. With such broad applications, mistakes during filling can affect entire operations.

Recognizing Propane Tank Types

Before discussing filling, it helps to understand tank categories. Portable cylinders, such as those for grills and patio heaters, are usually 20-pound units designed for easy exchange or refill at filling stations.

Larger stationary tanks serve homes and commercial sites, ranging from 100 gallons to more than 1,000 gallons. They supply furnaces, water heaters, and other appliances through fixed piping.

Each category comes with unique filling methods. Portable tanks are moved to a refilling location, while stationary tanks are filled directly from a propane delivery truck. Both require close attention, but the equipment and process differ.

For more about propane service in Pennsylvania and Maryland, visit Aero Energy’s page on propane.

Steps in the Filling Process

Filling a propane tank involves more than attaching a hose. Each step plays a role in keeping people safe and equipment intact.

The first step is inspection. Tanks should be checked for visible damage, rust, or dents. Valves must also be examined for cracks or wear. A damaged cylinder should never be filled.

Next comes the purge for new tanks. A tank fresh from the factory may contain air or moisture. Purging removes these contaminants. Without this step, performance issues may arise.

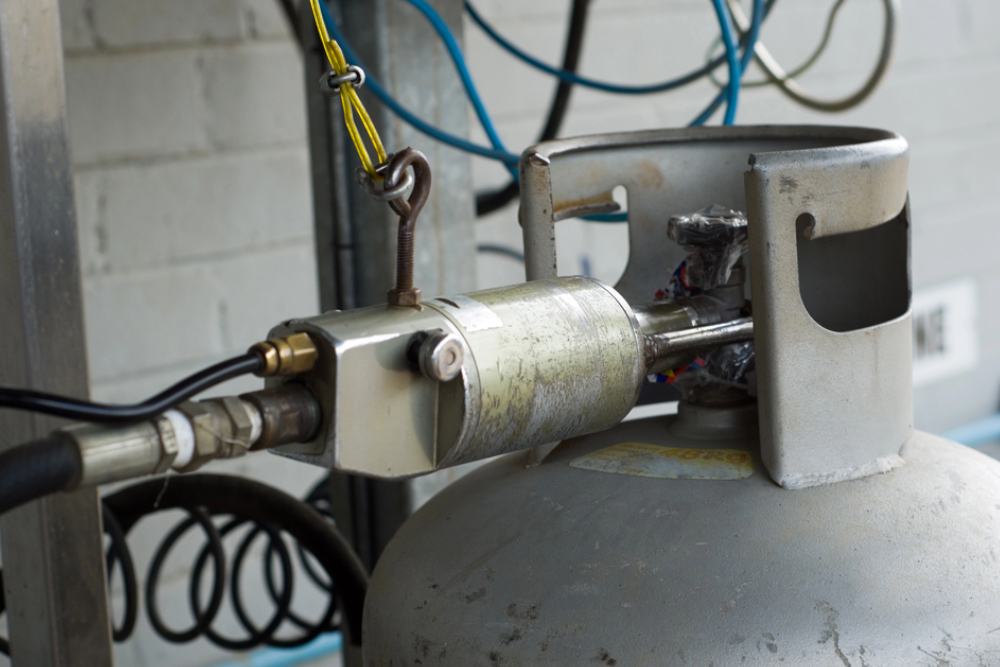

Once the tank is ready, a certified technician connects the hose from a bulk storage source. For small cylinders, a fill valve attaches directly to the service valve. For larger stationary tanks, the hose from the delivery truck is connected to the fill valve on the tank dome.

The technician monitors the process with gauges and safety devices, carefully stopping the fill at about 80 percent capacity. Leaving this expansion space is essential, as propane increases in volume when warmed, and the margin helps prevent dangerous overpressure.

Finally, valves are closed, hoses are detached, and leak checks are performed. Soap solution is often applied around connections to test for bubbles that signal escaping gas.

- Safety Checks During Filling

A series of safety checks helps keep the filling process under control. First, the tank’s certification date must be current. In the United States, portable cylinders require requalification after 12 years and every 5 years thereafter, and any cylinder past its date cannot be legally filled.

Technicians also verify that overfill prevention devices (OPD valves) are installed. These triangular-handled valves automatically limit the amount of propane that can enter the cylinder. While most modern portable tanks are equipped with OPD valves, older models may not include this feature.

Temperature monitoring is another key safeguard. Because propane expands as it warms, filling beyond safe levels during cold conditions could create excessive pressure once temperatures rise, making proper attention to fill limits essential for safe operation.

- Recognizing When a Tank Needs Filling

Running out of propane can be inconvenient or even dangerous in cold weather. Watching for signs helps avoid unexpected shortages.

For portable cylinders, weight is the simplest indicator. A full 20-pound cylinder weighs about 37 pounds, while an empty one weighs around 17 pounds. Scales are often available at filling stations.

Stationary tanks feature a gauge near the dome that shows the percentage of fuel inside. A reading of 20 to 30 percent usually signals that it is time to order more propane.

Many customers also use automatic delivery services. With these, fuel use is tracked based on weather and prior consumption patterns, and deliveries are scheduled before levels drop too low.

- Safe Storage of Propane Tanks

Proper storage is just as critical as the filling process. Portable cylinders should always be stored outdoors in an upright position, never inside a house, basement, or garage. Adequate ventilation is essential, as even a minor leak can accumulate in enclosed areas and create serious risks.

Stationary tanks must also remain accessible and free of obstructions. Grass, snow, and debris should be cleared away, and a safe clearance zone should be maintained between tanks and nearby structures. This spacing reduces hazards and allows emergency personnel, such as firefighters, to reach the tank quickly if needed.

In warmer months, tanks should not be left in direct sunlight for extended periods. Providing shade or a protective covering helps limit pressure buildup and keeps the system operating safely.

- Training and Certification for Filling

Handling propane tanks is not a responsibility for untrained staff. Regulations require that only certified personnel carry out the filling process, with many states mandating formal safety courses and strict compliance with handling standards.

Training programs cover essential topics such as proper connections, safe filling limits, and emergency shutoff procedures. Certification confirms that workers are prepared to respond effectively if an issue arises. For stationary tanks, delivery drivers often complete additional specialized instruction to address the complexities of large-scale systems.

This structured approach protects both employees and customers, promotes consistency across operations, and reduces the likelihood of costly or dangerous mistakes.

- Understanding Propane Safety Features

Modern propane tanks include several built-in features that promote safe operation. OPD valves prevent overfilling. Pressure relief valves allow gas to escape if the tank becomes too hot. Excess flow valves limit gas release if the hose is damaged.

Gauges also play a key role. Portable cylinders may use a simple float gauge, while stationary tanks often use more precise dial gauges. Reading them accurately is an important skill during filling.

Aero Energy outlines more information about safe handling practices on its propane safety resource page.

Call Aero Energy For Safe Propane Service

Safe filling of a propane tank depends on proper technique, regular inspection, and awareness of safety features. By following best practices, risks are reduced, and fuel systems operate with